Ott Topedge Edgebander

Edgebanders | Listed: 26th Oct, 2018

Ott Topedge edgebander - edgebanding on the highest level

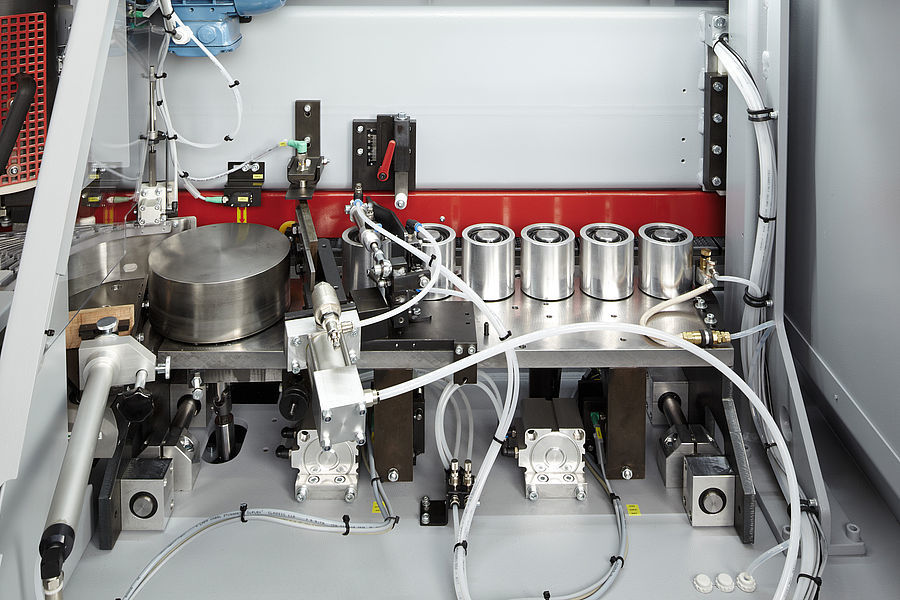

Standard equipment

- Combi-Melt gluing for EVA and PUR system with 2.5L container and filling pipe

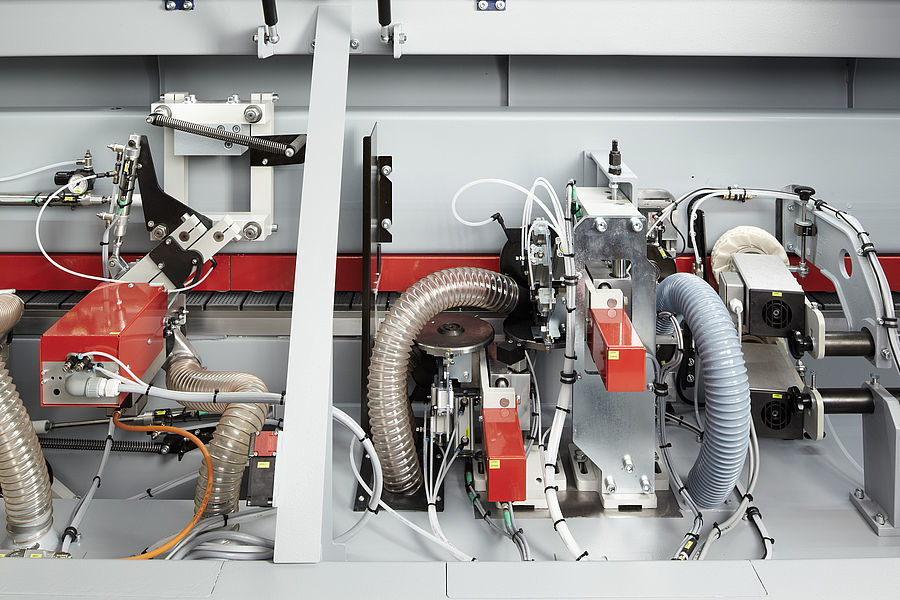

- Pre-milling unit

- Feed with 5.5kw drive with automatic lubrication

- Heated infeed fence

- Automatic magazine for strip edges

- Synchro-Flex driven top pressure belt system

- Coil magazine with guillotine

- Nesting package

- Double end trim

- Rough trimming unit

- Bevel trimming unit

- Radius trimming unit

- Profile scraper changer

- Automatic corner rounding and trimming

- Flat scraper

Options that can be added or changes the standard equipment

- Infeed slide pusher for panels

- Coil magazine for 2 coils

- Automatic coil magazine for 8 coils

- Coil administration with creation of bar code and identification

- Trans-Start automated infeed aid

- Package for processing up to 25mm edges

- Equipped for panel thickness 80mm

- Air cushion table with vacuum generator

- Large automatic edge magazine

- 2 Spray mist devices with antistatic agent

- Spray mist device for sensitive edge material

- Quick change set

- Set for narrow pieces

- Buffing unit

- Cleaning set

- Sanding unit

- Grooving unit

- Universal grooving unit

- Structure brushing unit

- Universal brushing unit

Technical Data

| Machine length | 8600 , 9300 & 10300 mm (depends on equipment required) |

| Minimum panel width | 70 mm |

| Minimum panel length | 150 mm |

| Panel thickness | 8 - 60 mm |

| Edge thickness | 0.3 - 20 mm |

| Feed speed | 14 -20 m/min |